Another way is adjusting the size based on your material size. You can set the “Object Size” when you need a defined size. This can be set to a fairly huge size (the laser cutter at the University of Applied Sciences Potsdam (Germany) has a size of 1200 mm to 900 mm). The manufacturing settings allow you to set the size of your material. When you import your 3D model you first need to set some options. We will cut them with different settings leaving a visual mark where to fold your material. The marks for the folding lines are enough to.

Which is fine for something like cosplay foam armor and so forth but again doesn't really work for me most of the time. The other program that people use alot for this type of work flow is pepakura, which basically takes a 3d model and converts it to a flat pattern kind of like what the sheet metal function does for a sheet metal piece.

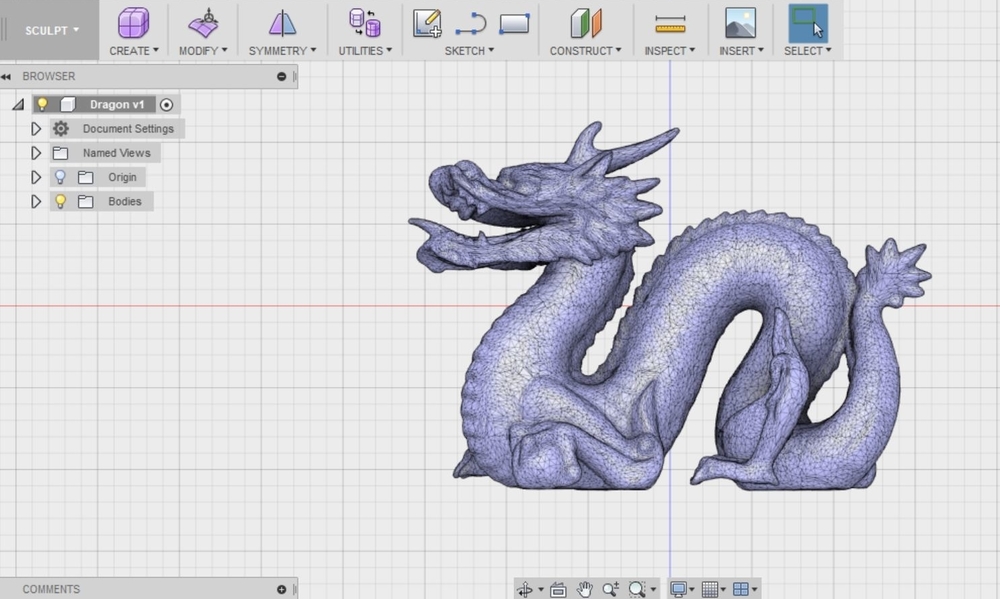

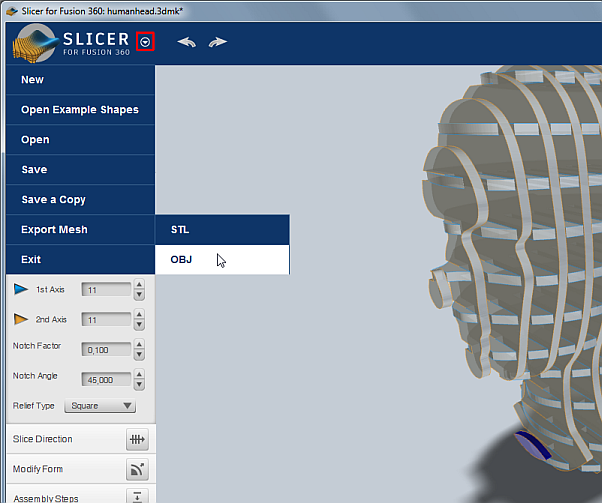

That's why I haven't really found a suitable replacement for the "slicer for fusion" program. obj and results in perfectly created patterns from the geometry. Where as the independent slicer for fusion program works directly from the. Which makes the patterns on the drawing very sloppy and inaccurate. Most of the time even if I slice the model into the layers I need (ranging between 4mm and 12mm thick due to foam thickness) to simplify them before converting them, the resulting geometry if very prismatic because to the way the surfaces are created. I can convert them to a solid, but then there's an issue where fusions limitation on how detailed the surface can be for conversion, I run into issues. Those models come in as surfaces, which unfortunately can't be printed on a drawing to make the patterns I need. obj files from sites like thingiverse or turbosquid. Most of the models I'm using aren't solid bodies. Unfortunately the work flow to get to that point is the issue. Thank you for putting together the video.

0 kommentar(er)

0 kommentar(er)